Professional A3 DTF Printer and 60cm DTF Printer Manufacturer

Professional A3 DTF Printer and 60cm DTF Printer Manufacturer

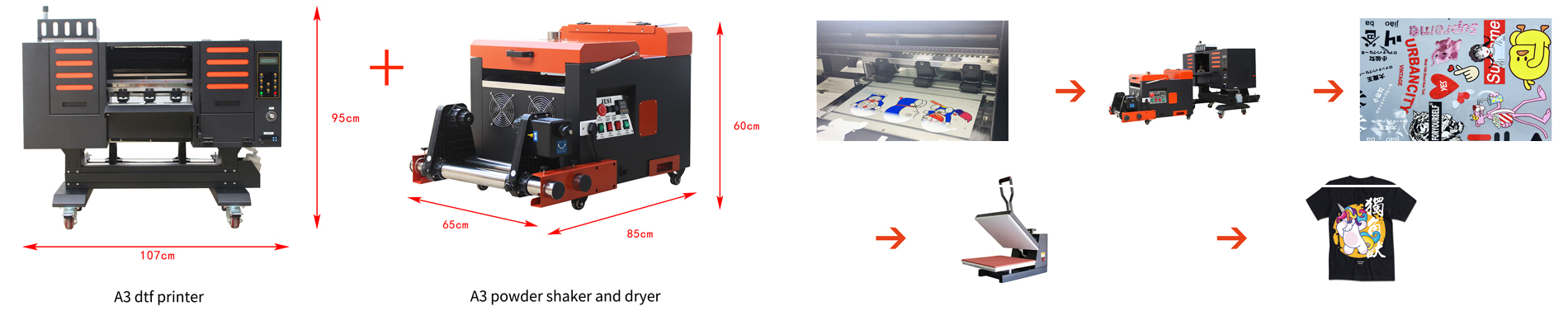

What is heat transfer process?

The heat transfer process in Visual-Tex DTF Film printer is a process technology that uses dot printing (resolution up to 300dpi), pre prints the pattern on the film surface, and then transfers it on the product surface. In this way, the patterns formed by printing have rich levels, bright colors, changeable patterns and small color difference, which greatly improves the grade of products, can meet the requirements of customers for patterns and colors, and is suitable for mass production.

Classification of heat transfer process in Visual-Tex DTF Film printer

In the Visual-Tex DTF Film printer, clothing heat transfer is the most widely used, but there are two common heat transfer methods:

(1) Sublimation heat transfer

In short, sublimation heat transfer printing is to print disperse dyes on specific paper by printer in advance, and then transfer the patterns on the paper to the cloth to be printed with high temperature and high pressure to complete the whole heat transfer printing process.

(2) Heat transfer hot stamping

Different from the sublimation heat transfer printing method, the printing material does not have the sublimation effect like the sublimation dye. The printing material will not penetrate into the fabric fiber under high temperature and high pressure. Although it can also be pressed and ironed by the transfer printer, it is only attached to the surface on the clothing, which not only has poor hand feeling, but also greatly reduces the air permeability of the clothing.

Advantages of heat transfer process:

(1) Simple printing

The thermal transfer process does not need the steps of plate making, plate printing and repeated color registration, and does not need all kinds of tools and materials required by screen printing and transfer. It only needs one computer and one operator to complete the printing operation. The method is simple and desirable.

(2) Accurate location

The thermal transfer printing process avoids the position offset problem that is easy to occur in the process of manual printing, and can accurately align the area and position of the time required. At the same time, because it is a one-time printing, it also avoids the problem of color registration and alignment. Therefore, the printed pattern is too fine and greasy, and the picture quality is more accurate and excellent.

(3) Multicomponent printing

As far as the digital printing industry is concerned, there are professional industry distinctions, such as the traditional printing in the leather industry: screen printing has a single color and simple transition color; Large leather printing printers are expensive and have high requirements for materials; The plexiglass industry needs screen printing technology, while the crystal industry needs crystal film pasting technology and so on. By using the heat transfer process of Visual-Tex DTF Film printer, the process problems required by all materials can be solved at one time, and any object can be printed. Therefore, the Visual-Tex DTF Film printer of heat transfer printing has also become a universal printer.

As long as a computer, a printer equipped with heat transfer ink and a Visual-Tex DTF printer, the equipment can print images on any solid object and any curved surface at will, with the characteristics of clear pattern, bright color, realistic effect and strong adhesion. Can accept all kinds of personalized customization, on-site production, widely used, everywhere! This is also the reason why heat transfer printing has become a favorite.

Zhengzhou Visual-Tex used advanced and practical technology to design and produce wide format printer, DTF printer direct to film printer, digital sublimation printer, eco solvent printer and UV printer and other mature products, which are well known in the national photo machine industry. the products are exported to Europe, America, South America, Southeast Asia, the middle east and Africa, and in many countries and regions around the world to establish a distribution network and service system.