Professional A3 DTF Printer and 60cm DTF Printer Manufacturer

Professional A3 DTF Printer and 60cm DTF Printer Manufacturer

When the upsurge of clothing textile, personalized custom hot stamping and private customization surged everywhere, a new printing process swept the clothing printing industry at home and abroad, which is now the mainstream offset hot stamping process. Why is Kirsch’s hot stamping so popular? How to realize printing? How about the hot stamping effect?

Printing principle

For example, Visual-Tex DTF printe is a new process of hot stamping on clothes through hot stamping direct jet printing on the heat transfer film and hot melting of ink on the surface of the pattern as a transfer medium;

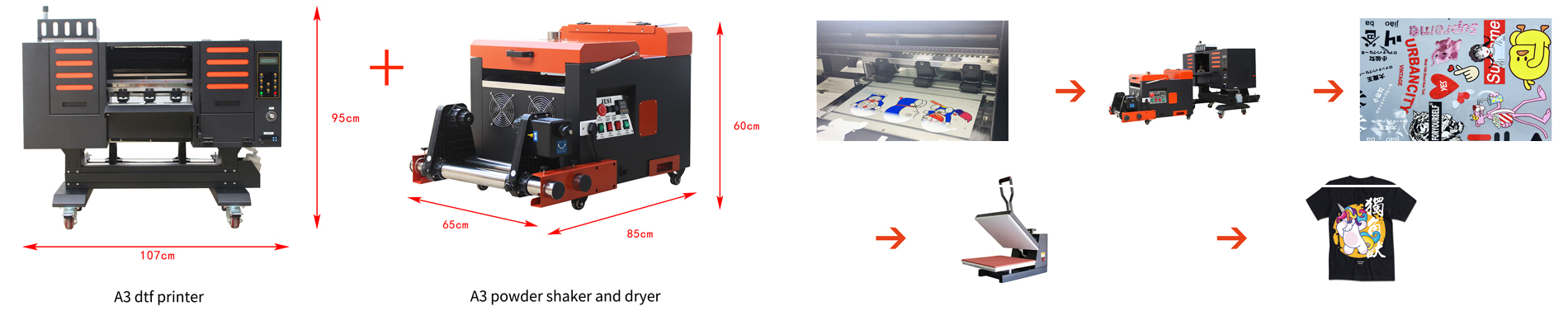

Print steps

1. The hot stamping film printer uses special ink to spray directly on the pet transparent film, and the printed pictures are full of color and clearly visible;

2. Melt and dry the hot-melt adhesive on the pattern through the oven, baking lamp, hot-air gun, etc. of the powder shaker (hot-melt powder drying equipment);

3. After cutting the pattern, set the hot stamping temperature at 150-160°C and press for 10 seconds through the electric / manual hot transfer press;

4. Remove the PET film on the clothes from the clothes, complete the hot stamping, wash and rub the pictures without separation and high color fastness;

Print effect

Cartoon characters, English letters and other clothing elements are hot stamped on clothes, which are bright in color, not easy to decolorize, not easy to layer and not easy to crack; In addition, there are no restrictions on cloth, one printing, no plate making, fast delivery and other advantages. It has become a new hot stamping process recognized by clothing design and personalized clothing customization, which has been widely appreciated by people in the clothing and digital printing industry.

Printing equipment

The Visual-Tex DTF film printer VT300 is equipped with an original i3200 print head. It can be produced by heat transfer and hot stamping. Strengthen the hardware foundation, high configuration operations such as rexay servo motor, imported silent linear guide rail, high-precision printing platform and Montaigne color management software, accurate positioning system and further improve the stability, which has won the trust and praise of customers with efficient printing.

Printing purpose

In this diversified market, personalization and uniqueness are the key to attract consumers. Visual-Tex has always been at the forefront of the hot stamping printing industry and provides customers with high-quality solutions. The products are used in advertising production, leather printing, textile printing and dyeing, clothing printing, digital photo, banner and other printed fabrics, outdoor advertising and decorative products.

Zhengzhou Visual-Tex used advanced and practical technology to design and produce wide format printer, DTF printer direct to film printer, digital sublimation printer, eco solvent printer and UV printer and other mature products, which are well known in the national photo machine industry. the products are exported to Europe, America, South America, Southeast Asia, the middle east and Africa, and in many countries and regions around the world to establish a distribution network and service system.